The Problem

- Metals and non-metals in printed circuit boards (PCBAs), Solar Panels, and Lithium Ion Batteries are bound together in the manufacturing process, making them difficult to separate even when size reduced.

- E-waste recycling is still very much in its infancy, but recovery networks throughout North America and Europe have begun to emerge and are growing. The term “urban mining” has been coined to describe the collection, sorting, and channeling of e-waste.

- In most e-Waste sorting processes, the end products are a light-weight plastics fraction and an intermediate metallics fraction. The metallics fraction contains gold and copper values, but also many other metals, including; lithium, cobalt, manganese, silver, nickel, tin, lead, platinum, palladium, neodymium, aluminum, and iron. These metallics are bundled into supersacks and shipped off to smelters, where only a portion of the full metal value is actually recovered.

- The raw materials contract for e-waste will typically include a payable for copper and gold, minus smelting & refining charges. Penalties are also applied to deleterious elements, such as lead, tin, and nickel. Depending upon concentration, there may or may not be payables for silver, platinum group metals [PGMs] and rare earth elements [REEs].

The Solution

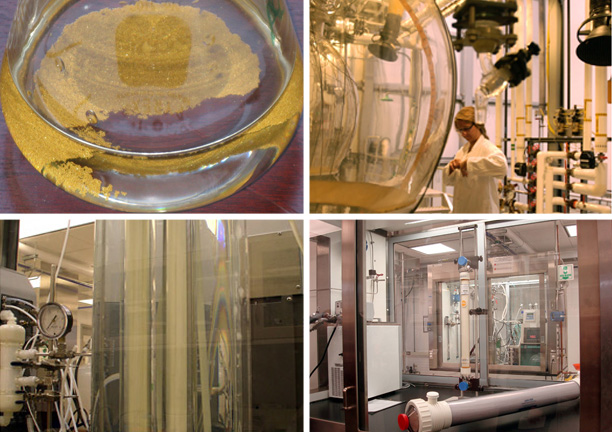

Out of Ronin8 Laboratories, a revolutionary new e-Waste/Gold process has been developed. Built around a device that dissolves gold with astonishing efficiency, the Ronin Process recovers .9999 pure gold in considerably less time and at a fraction of the cost of conventional procedures.

The process is ideally suited to all e-Waste and gold scrap. Raw materials ranging from computer chips to heavy gold chain can be dissolved in a matter of a just a few hours using reagents that are safe to manage and do not pose a threat to the environment. Unlike aqua regia based processes, no noxious fumes are generated and the recovery step that immediately follows gold dissolution produces a beautiful coarse-grained product that is easily filtered and washed.

Gold recovery is 100%

Our process recovers all metals and non-metals at rates comparable to or exceeding other alternatives and with additional operational and environmental benefits.

- It is the availability of the metallics, coupled with the penalties for deleterious elements, and the fact that smelters never realize full value for the contained metals, which has led Ronin8 to its assertion that an opportunity can be created through the introduction of a clean-technology metals recovery process that also recovers Silver, PGMs, Tin, and base metals such as Copper, Manganese ~ without incurring losses, without generating pollutants, without costly delays nor costly energy expenditures.

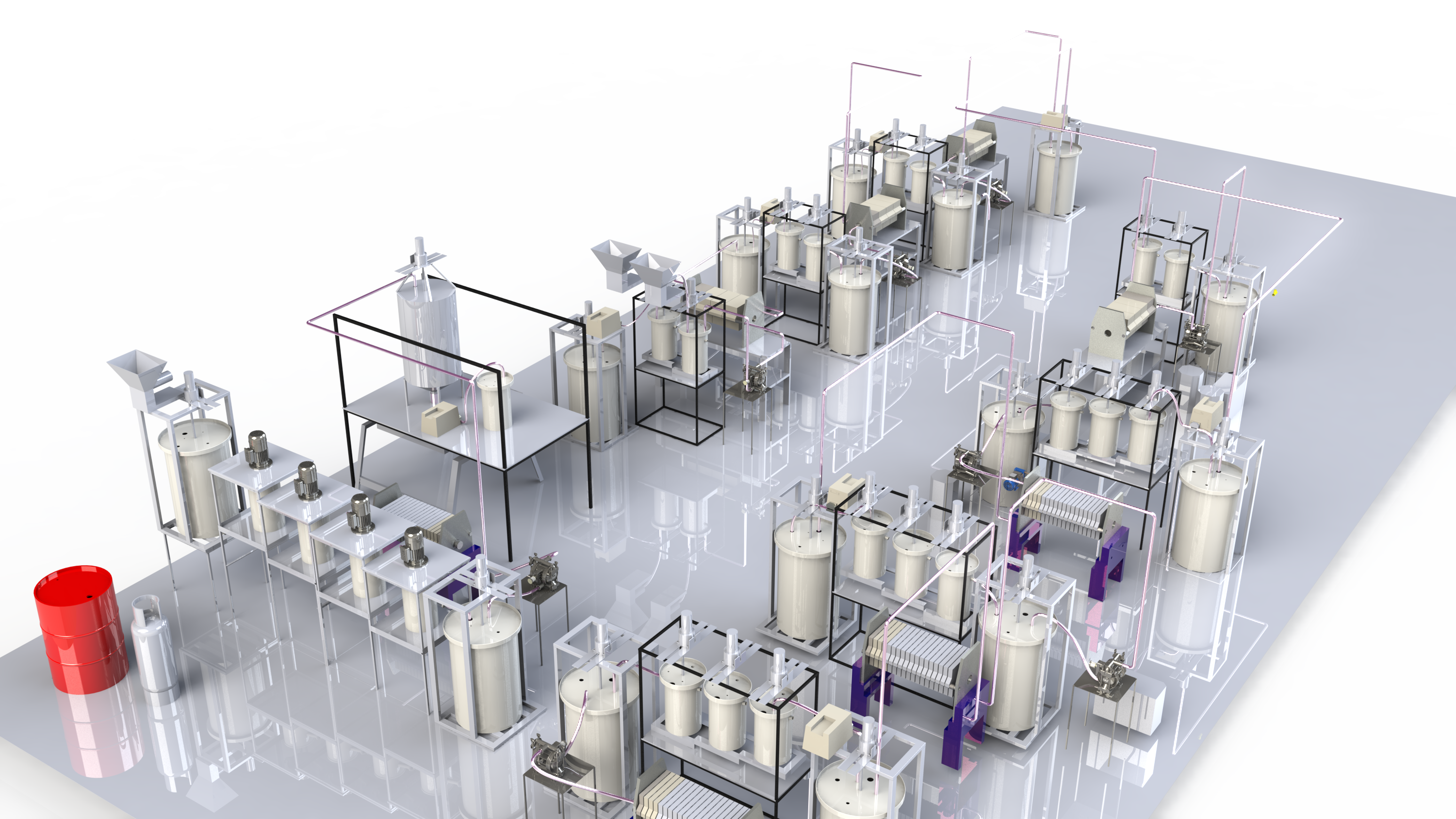

Proprietary RONIN8 Reactor

The heart of the Ronin8 e-Waste/Gold Process is a revolutionary reactor design that accelerates dissolution, beyond anything that is presently being utilized. These Reactors are modular, one standard size can be manufactured and scale-up achieved by adding units to the process to match raw materials input.

- Pure gold [99.999 %] is produced.

- All gold is recovered.

- > 95% of gold is recovered in less than 24 hours.

- Remaining gold is recovered in less than 48 hours.

- No pre-processing required – gold scrap and e-waste are treated whole.

- Gemstones are recovered undamaged.

- CPUs and other e-waste are stripped clean.

- Does not use aqua regia or cyanide.

- No noxious fumes.

- Compact, Securitized & Secured remotely

- Modular system ensures reliable scale-up.

- Low reagent cost – $2-3 / Troy oz.

- Copper and other base metals can be recovered for by-product credit.

- A platinum group metals (PGM) recovery circuit can easily be added.

- Environmentally friendly.

Our Prototype Facility in Richmond, BC was fully commissioned in January 2016, followed in 2019 with opening of our primary plant facility located in Montreal, Quebec. Through operating this facility we have accumulated critical operational and engineering data and invaluable process expertise to support our commercial scale-up.

BC Technology Impact Award (BCTIA)

Recycling Council of BC (RCBC) Innovation Award

Innovation Award of the Year offered by the Canadian Government